Precision parts polishing is a technical job that requires certain skills and steps. This article will detail the steps and key techniques of polishing precision parts to help readers better understand this field.

First, polishing steps

Rough polishing

Rough polishing is the first step of precision parts polishing, the main purpose is to remove the parts surface burrs, oxide layer and rough parts. Some mechanical polishing methods can be used, such as sandpaper polishing, lapping machines and so on. Before polishing, it is necessary to prepare the required tools and materials, including sandpaper, lapping machine, polishing agent and so on. At the same time, the surface of the part should be carefully inspected for defects, such as rust, scratches, etc.

Intermediate polishing

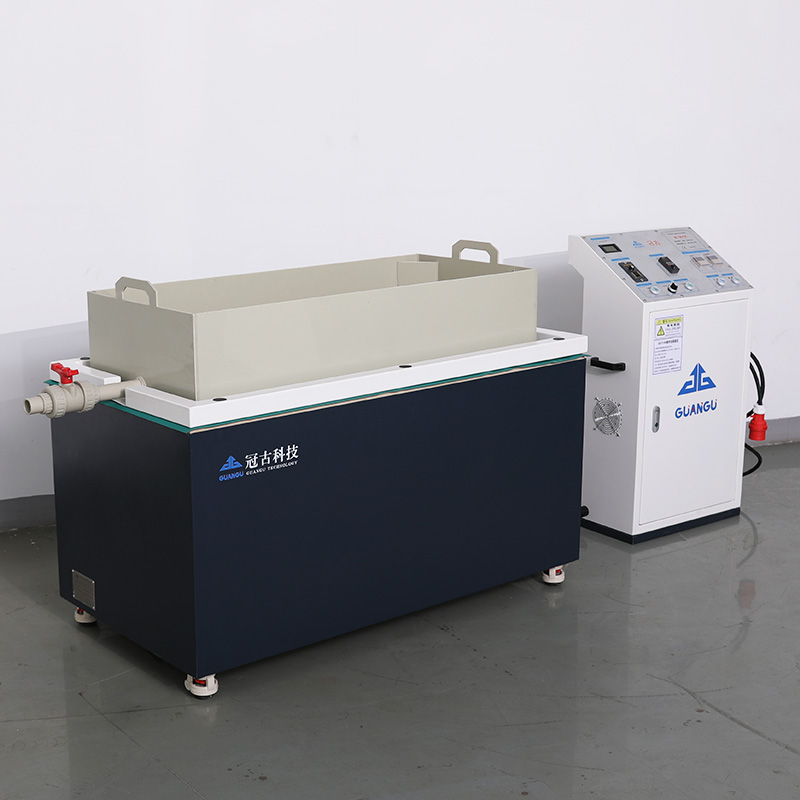

Intermediate polishing is the second step of polishing precision parts, the main purpose is to further smooth the surface of the parts and remove the traces left after rough polishing. Some chemical polishing methods can be used, such as electrolytic polishing, acid washing and so on. Before polishing, it is necessary to understand the nature of the part material and the principle of selection of polishing agent in order to select the appropriate polishing agent. At the same time, it is necessary to master the polishing time and temperature to avoid excessive polishing resulting in damage to the surface of the parts.

Fine polishing

Fine polishing is the third step of precision parts polishing, the main purpose is to make the surface of the parts smoother, to achieve the expected accuracy and roughness. Some optical polishing methods can be used, such as ultrasonic polishing, magnetic grinding and so on. After polishing, the surface of the parts should be maintained, such as coated with anti-rust oil and wiped clean. At the same time, check whether the accuracy and roughness of the part surface meet the requirements, and rework or repolish if necessary.

II. Key Tips

Scratch prevention

Scratch prevention is one of the most critical skills in the polishing process of precision parts. Because the surface of precision parts is usually more fragile, it is easy to be scratched or bruised, so in the polishing operation, we must be careful to avoid the use of too rough tools or techniques. At the same time, when storing and transporting precision parts, it is important to use appropriate protective measures, such as foam pads, soft paper, etc., to ensure that the surface of the parts will not be scratched or bruised.

Regular Maintenance

Regular maintenance is another key tip for polishing precision parts. Since the tools and materials used in the precision parts polishing process may wear out or deteriorate, they need to be maintained and replaced on a regular basis. Generally, the replacement intervals for tools and materials can be determined based on usage and manufacturer's recommendations. At the same time, the performance and quality of tools and materials should be checked regularly, and any problems should be dealt with and replaced in a timely manner.

Grasp the details

Grasping the details is the third key skill in polishing precision parts. Since the size and accuracy of precision parts are usually small, great attention to detail is required in the polishing process. For example, in the choice of polishing agent, according to the nature of the part material and the principle of polishing agent selection to choose the appropriate polishing agent. At the same time, when dealing with details, it is necessary to master the balance between precision and efficiency to avoid excessive treatment leading to damage to the surface of the part.

Conclusion:

Through the above introduction, we can understand that precision parts polishing is a technical job that requires certain skills and steps. In the three steps of rough polishing, intermediate polishing and fine polishing, it is necessary to choose the appropriate tools or methods respectively, and pay attention to the key skills of scratch prevention, regular maintenance and grasping the details. Through the study of this article, readers can better understand the process of precision parts polishing and key skills